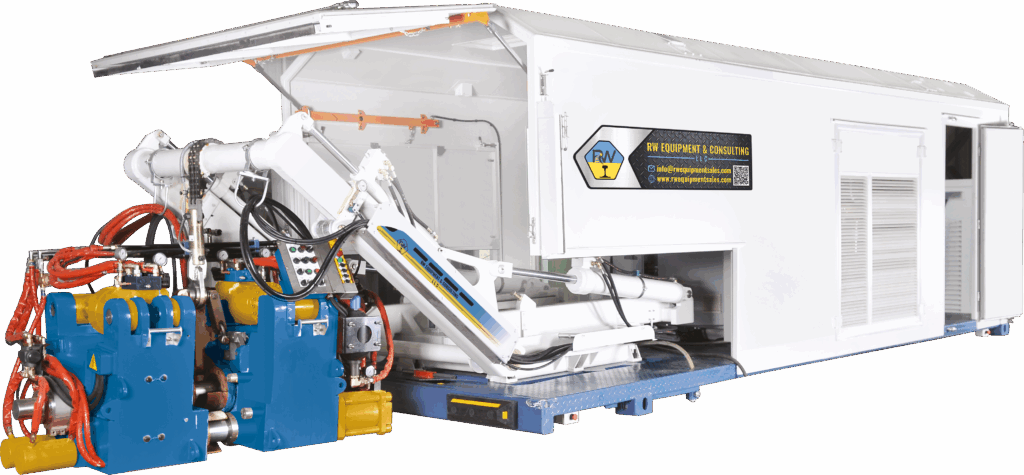

The container is equipped with all the necessary systems for efficient and

uninterrupted flash butt rail welding. It includes a powerful 500 KVA GenSet

diesel generator, a hydraulic pump station, an integrated crane, and a cooling

system. Its flexible design allows it to be used as a mobile, stationary, or

platform-based station, ensuring effective rail welding in any environment.

Mobile, Stationary, Reliable. Our welding container is a mobile and versatile

solution for rail welding. It can be mounted on a vehicle chassis for on-site

operations, installed stationary on a workshop stand, or positioned on a

dedicated platform for long-term use. This flexibility ensures efficient welding in

any environment, from construction sites to maintenance depots.

The integrated crane has a rotation range of 86° in either

direction and can extend from 0 to 12 feet (3.65 m). With a

lifting capacity of 5 tons, it enables rail welding both inside

and outside the track.

The container is equipped with a high-performance GenSet

diesel generator rated at 500 KVA, providing power for the

welding process and auxiliary operations. The generator

meets modern emission standards, making it suitable for

tunnel operations due to its reduced emission levels.

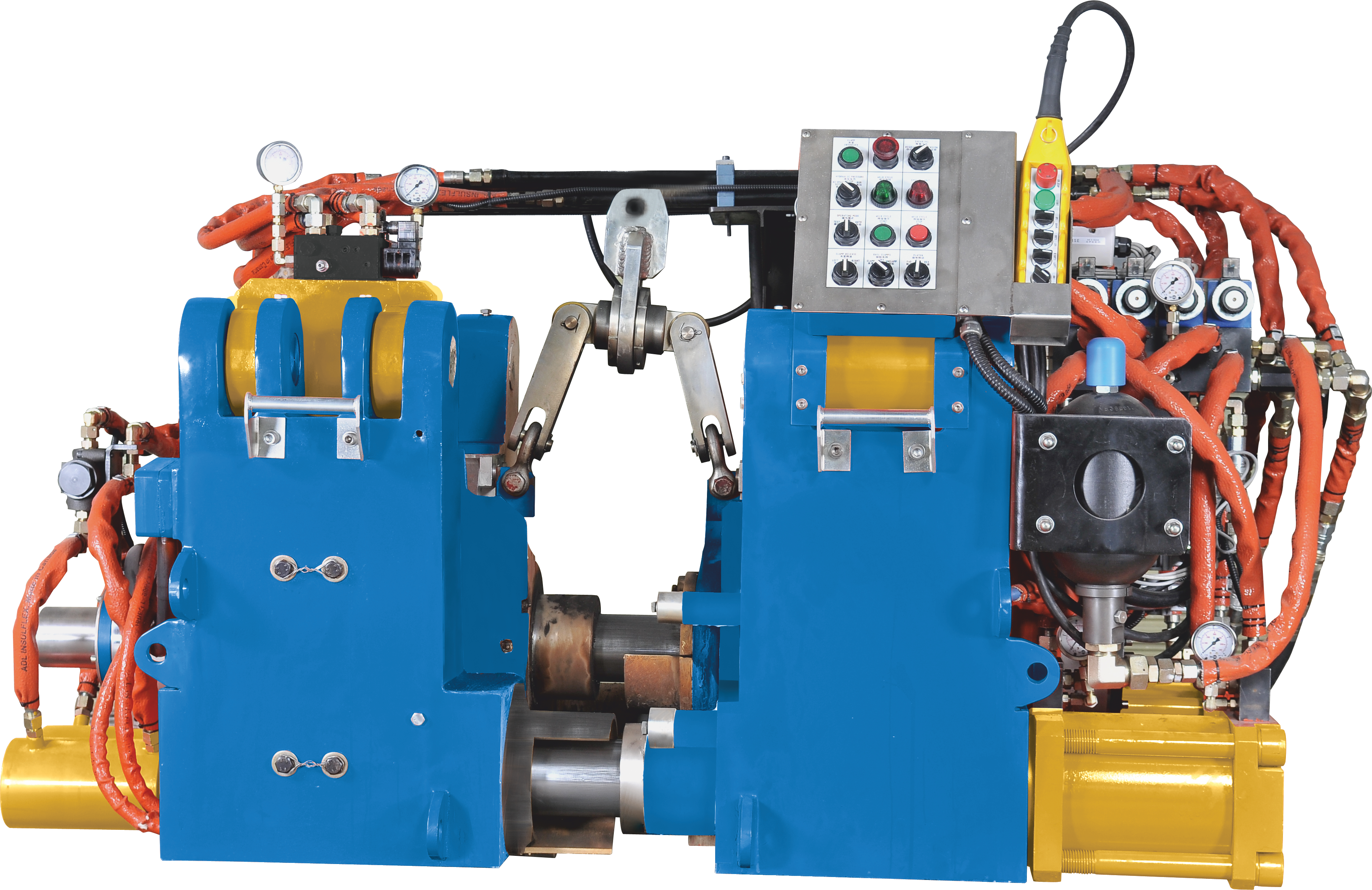

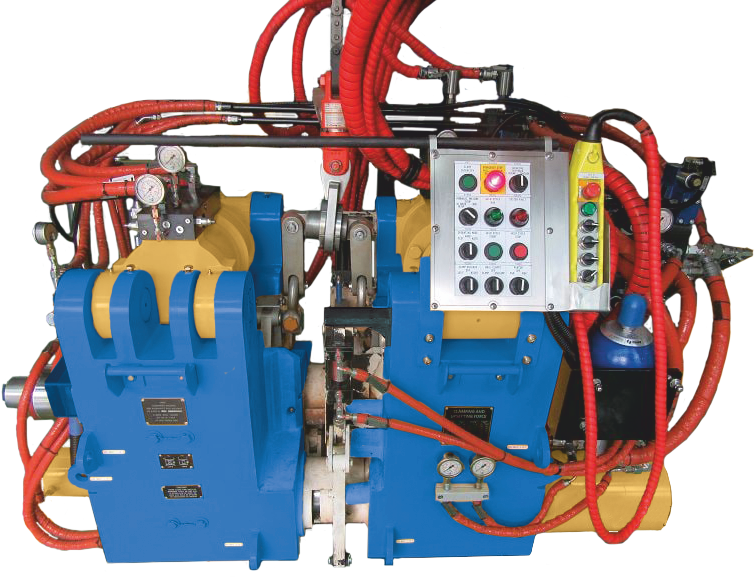

The pump station supplies hydraulic power for welder positioning on the rails and executing complete welding sequences. It features an automatic pressure control system with a BOSCH proportional relief valve, pre-piped and mounted on the tank. A high-pressure filter system is installed at the pump pressure port, while a 10-micron filter is placed on the return line. Additionally, a fine filter is integrated into the hydraulic manifold at the control servo valve. The oil circulation system, consisting of an auxiliary pump, cooler, and filters, maintains fluid stability and a constant temperature.

The container is equipped with a powerful cooling system that includes an additional hydraulic pump to circulate oil through a high-capacity air/oil cooler. The cooled flow is directed through a return filter before re-entering the tank, ensuring constant cooling and filtration. The system features high-temperature and low-level warning lights, along with a low-level “SHUT DOWN” function for added safety. Containerised rail welders come with a specially designed cooler unit optimised for FB welding operations, maintaining an accurate coolant temperature range according to preset values. The temperature range can be adjusted via the chiller control panel. If required, the system can be upgraded with oil/coolant heat exchangers to meet customer specifications. This advanced functionality ensures efficiency, reliability, and durability, making the container an essential solution for railway construction and maintenance.

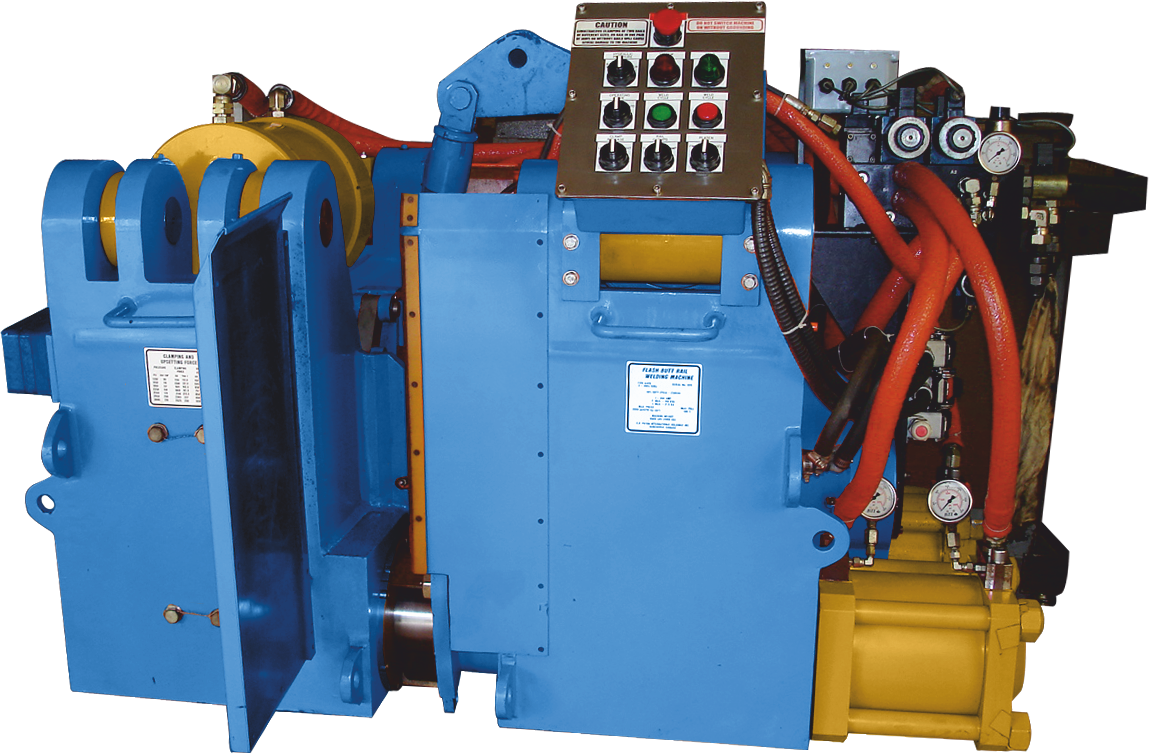

All products is fully compatible with our RW series welding heads, including RW20, RW22, RW30, and RW50. Designed for seamless integration, our products ensure optimal performance when paired with any of these models, providing reliability and efficiency in diverse working conditions.

Additionally, the service and maintenance procedures for our products follow the same standards as those established for the RW series welding heads. This guarantees consistent support, easy maintenance, and minimal downtime, keeping your welding operations running smoothly.