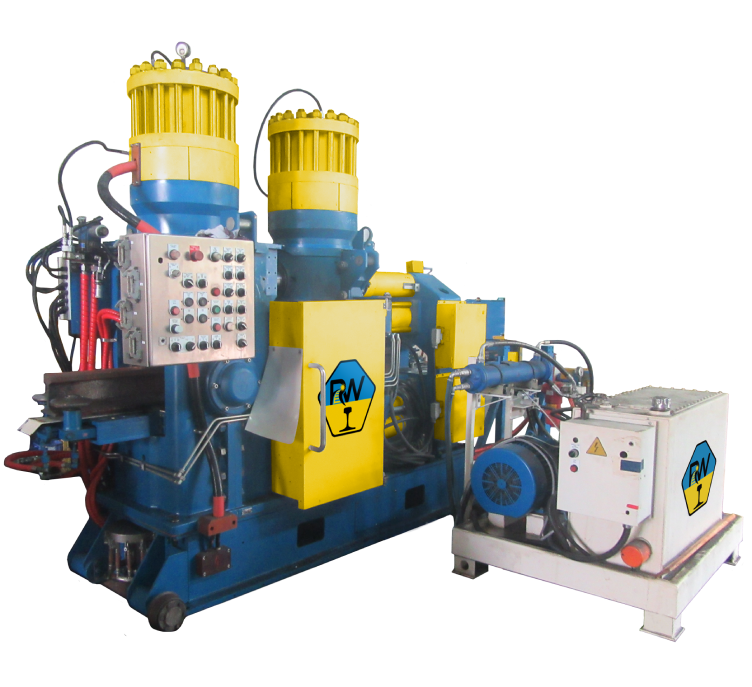

The Stationary RW1000 is a high-performance rail welding machine designed to

deliver consistent, high-quality welds with excellent strength and durability. It offers

energy efficiency, precise rail alignment, and advanced automation, making it ideal

for demanding railway applications.

After clamping, the machine allows for both vertical and horizontal rail alignment, with a tolerance of ±10 mm in both directions. Automatic axial rail alignment is also provided, ensuring precise placement during the welding process.

An integrated automatic shearing unit ensures clean and precise cuts. A built-in shield mechanism protects the shear and electrodes from weld splatter, while a fume and dust extraction system maintains a cleaner working environment.

The machine uses Regular and Pulse Flashing processes that ensure even and highly concentrated heating of the rail ends. This results in stable, consistent weld quality with high tensile strength and toughness, suitable for high-strength and alloyed rails.

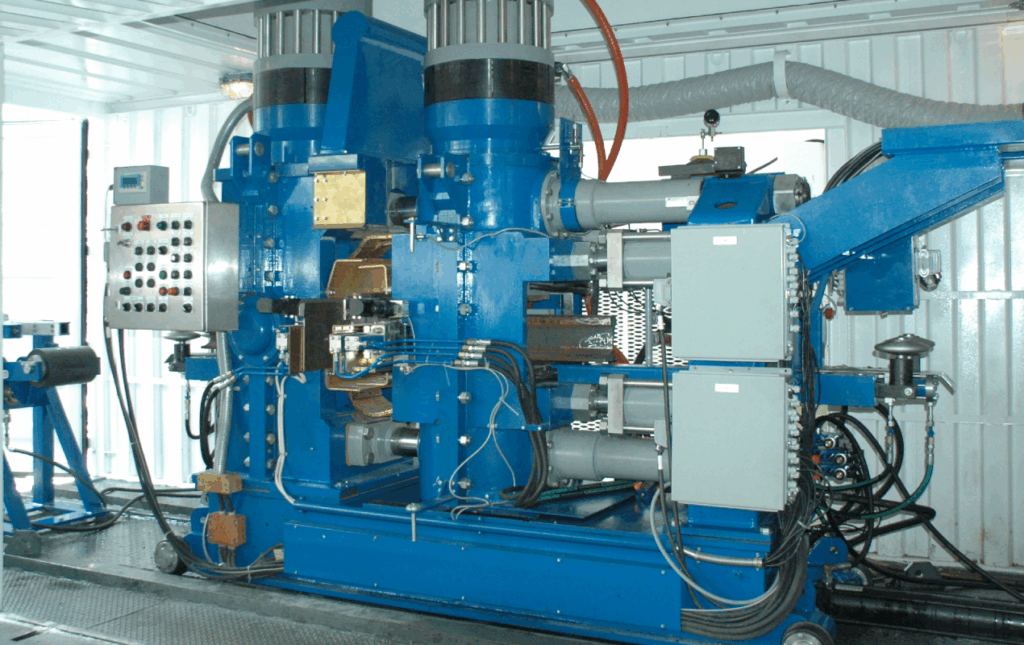

The machine offers high productivity, reaching up to 25 welds per hour, depending on the welding line’s production rate. The weld cycle duration is between 70-90 seconds for a 60 kg/m rail type. The machine is designed for low power consumption (210 KVA), with the option for symmetrical threephase loading. It has a power factor of at least 0.8. For remote operation, a containerised version can be supplied, powered by a diesel generator for easy relocation.

The Pulse Flashing process minimises rail metal consumption (10-15 mm), and the short upset process consumes even less (9-12 mm). The machine has low energy consumption, with only 2.0 KW/h required for one weld of a 60 kg/m rail type.

The machine provides free access to the electrodes, allowing for quick and easy changes. The computerised control system automatically manages welding parameters in both Regular and Pulse Flashing modes. Additionally, a computerised monitoring system performs operational control, providing detailed weld acceptability analysis upon completion of each weld. Each weld is assigned a unique number, and information about all welds is stored in the industrial computer’s memory.

Get the latest news about flash butt welding technology and our services directly to your inbox.