ATMW

All Terrain Mobile Welder

Different Warranty Options

Turnkey Maintenance Strategies

RW Welding Head Compatibility

Spare Parts

Staff Training

Mobility and Versatility

ATMW is designed as a fully functional mobile welding station, allowing work to be carried out on-site. Additionally, where certified, load towing is permitted. The excavator is equipped with an automatic hydraulic and air trailer braking system, compatible with GOS T Series rail trailers.

Combining advanced technology, high safety standards, and mobility, ATMW is the perfect solution for efficient railway construction and maintenance.

Power and Hydraulics

Hydraulic power is provided by the excavator’s main pump station. Engine-driven pumps supply power to both the excavator and the welder oil circuits. An integrated oil cooling system optimises continuous operation of the entire hydraulic system.

ATMW is a high-tech mobile welding system mounted on a Develon (formerly DOOSAN) DX170W excavator with rail equipment. Designed and manufactured by GOS Tools & Engineering Services Ltd (UK), this excavator is ideal for railway infrastructure construction and maintenance.

GOS Tool & Engineering Services Ltd. are a market leading manufacturer of Road Rail Vehicles (RRV’s) and specialist rail infrastructure installation and maintenance equipment solutions.

Autonomous Power Supply System

The equipment is mounted with a diesel generator and an integrated cooling system. An intelligent electronic control system ensures a stable welding process according to preset parameters, guaranteeing high-quality weld joints.

Reliability and Safety

RW Welding Heads Compatibility

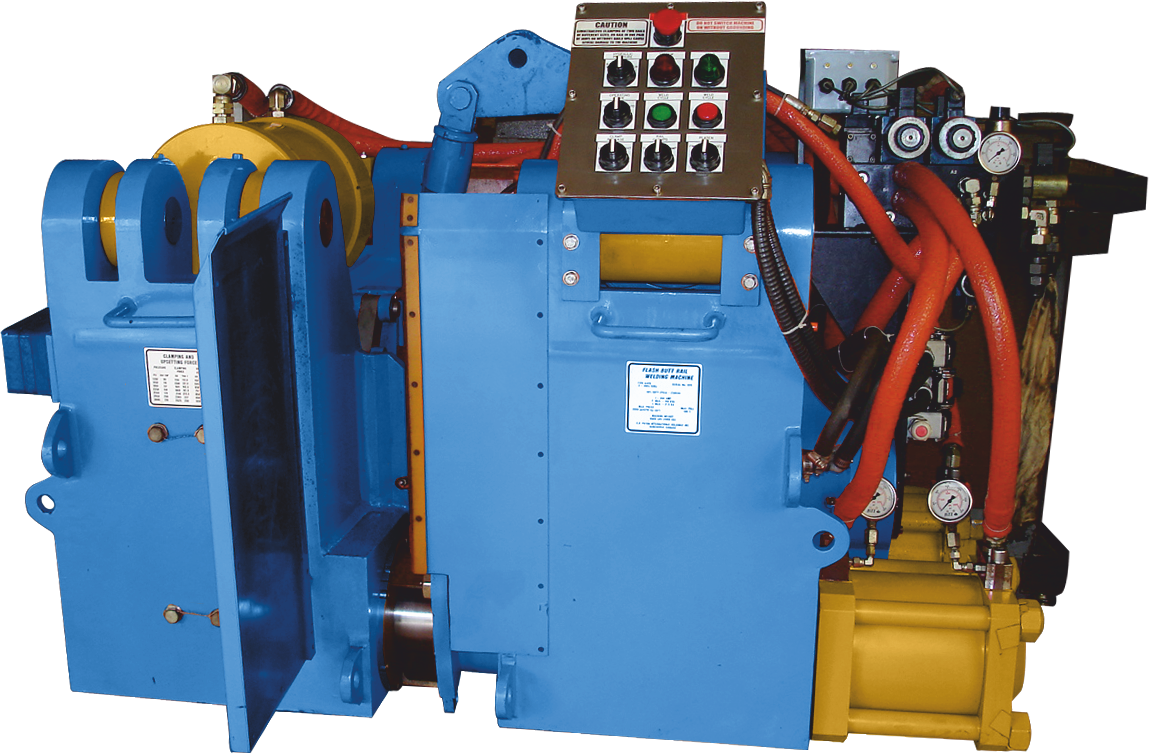

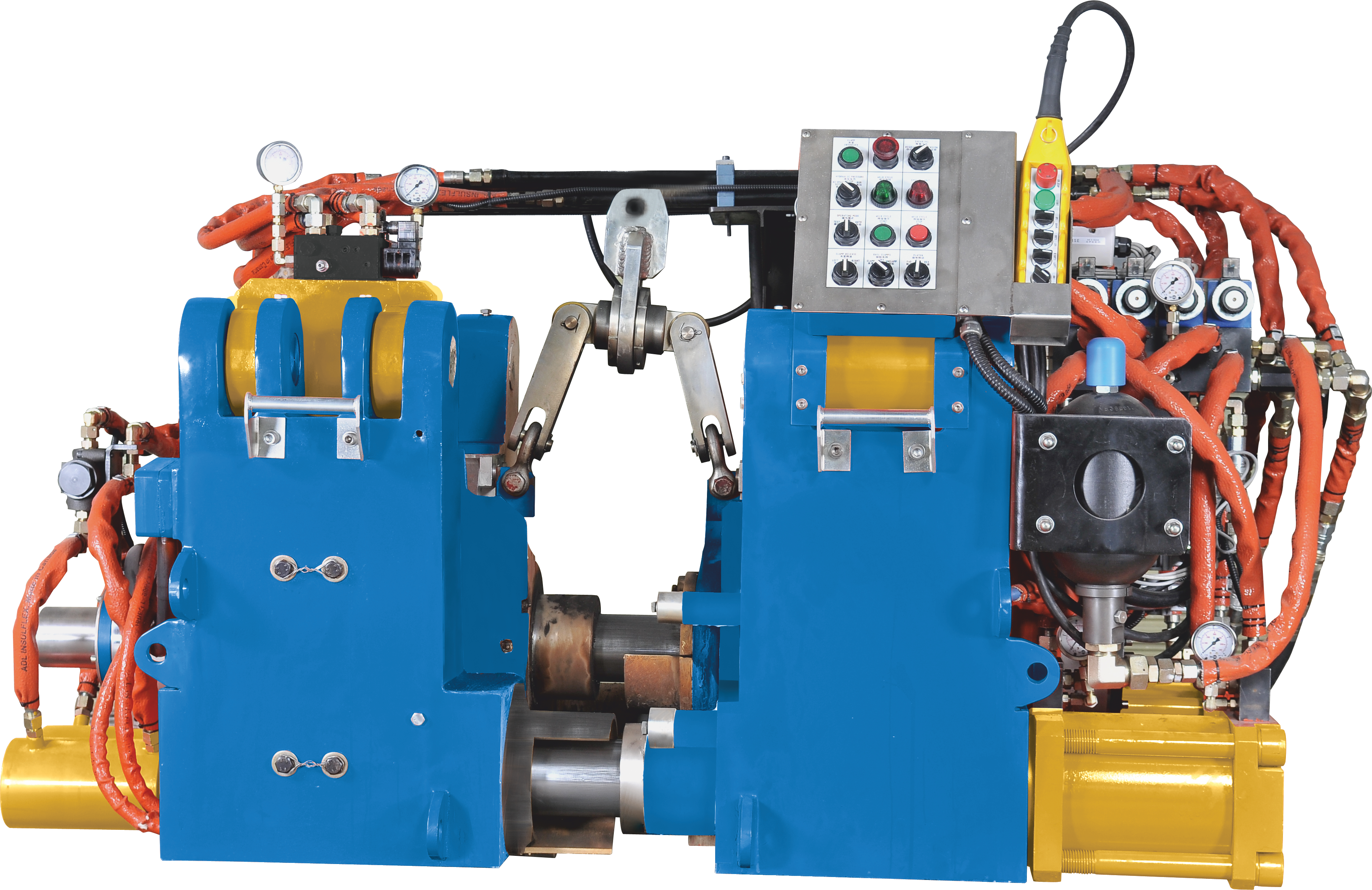

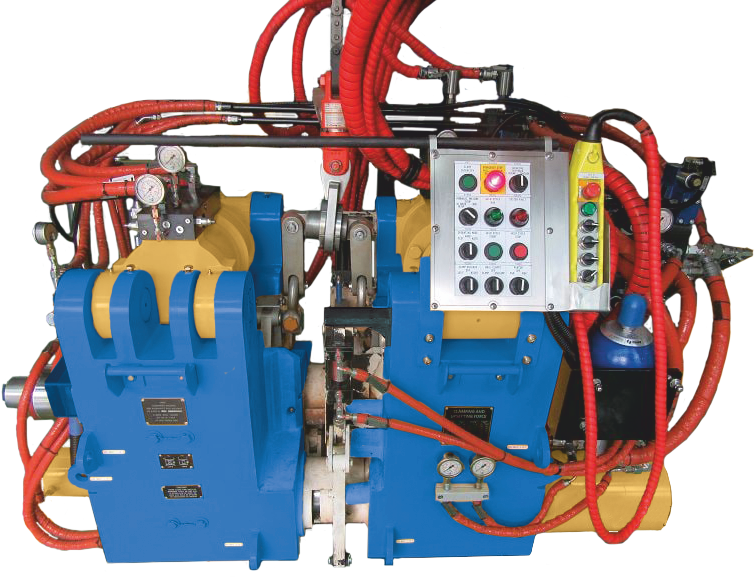

All products are fully compatible with our RW series welding heads, including RW20, RW22, RW30, and RW50. Designed for seamless integration, our products ensure optimal performance when paired with any of these models, providing reliability and efficiency in diverse working conditions.

Additionally, the service and maintenance procedures for our products follow the same standards as those established for the RW series welding heads. This guarantees consistent support, easy maintenance, and minimal downtime, keeping your welding operations running smoothly.

RW20

RW22

RW30

RW50

Seamless Integration with RW Products Ecosystem

Our welding heads are fully compatible with:

- ATMW (All Terrain Mobile Welder) – a mobile unit for full repair and welding operations.

- Container Solutions – modular, transportable systems for on-site deployment.

- WMS (Weld Monitoring Solution) – a digital platform for monitoring, planning, and analyzing welding

performance. - Welding Heads – optimal high-performance solution for flash butt welding.

Subscribe to our updates

Get the latest news about flash butt welding technology and our services directly to your inbox.